Enhance Your Business Environment with Non Skid Floor Coating

The importance of maintaining a safe and visually appealing environment in today's business world cannot be overstated. One effective way to achieve this is through the application of Non Skid Floor Coating. This innovative solution not only improves the safety of your floors but also contributes to the overall aesthetics of your workspace. In this comprehensive guide, we explore everything you need to know about Non Skid Floor Coating, its benefits, application methods, and how it can transform your business premises.

What is Non Skid Floor Coating?

Non Skid Floor Coating is a specialized product designed to provide traction on flooring surfaces. Commonly used in commercial and industrial settings, these coatings can be applied on various substrates including concrete, wood, and metal. The primary function of these coatings is to reduce the risk of slips and falls, making them an essential safety feature for any business.

Why Choose Non Skid Floor Coating?

There are numerous reasons why investing in Non Skid Floor Coating is beneficial for businesses. Here, we outline the key advantages:

- Enhanced Safety: The primary benefit is the significant reduction in slip and fall accidents, which can lead to serious injuries and liability issues.

- Improved Aesthetics: Available in a variety of colors and finishes, these coatings can enhance the look of your business space.

- Durability: Non skid coatings are designed to withstand heavy foot traffic and harsh environments, ensuring long-lasting protection.

- Easy Maintenance: These surfaces are typically easy to clean and maintain, which can save time and labor costs.

- Cost-Effective: Investing in a non skid coating can prevent costly accidents and improve your facility's longevity.

Application Areas for Non Skid Floor Coating

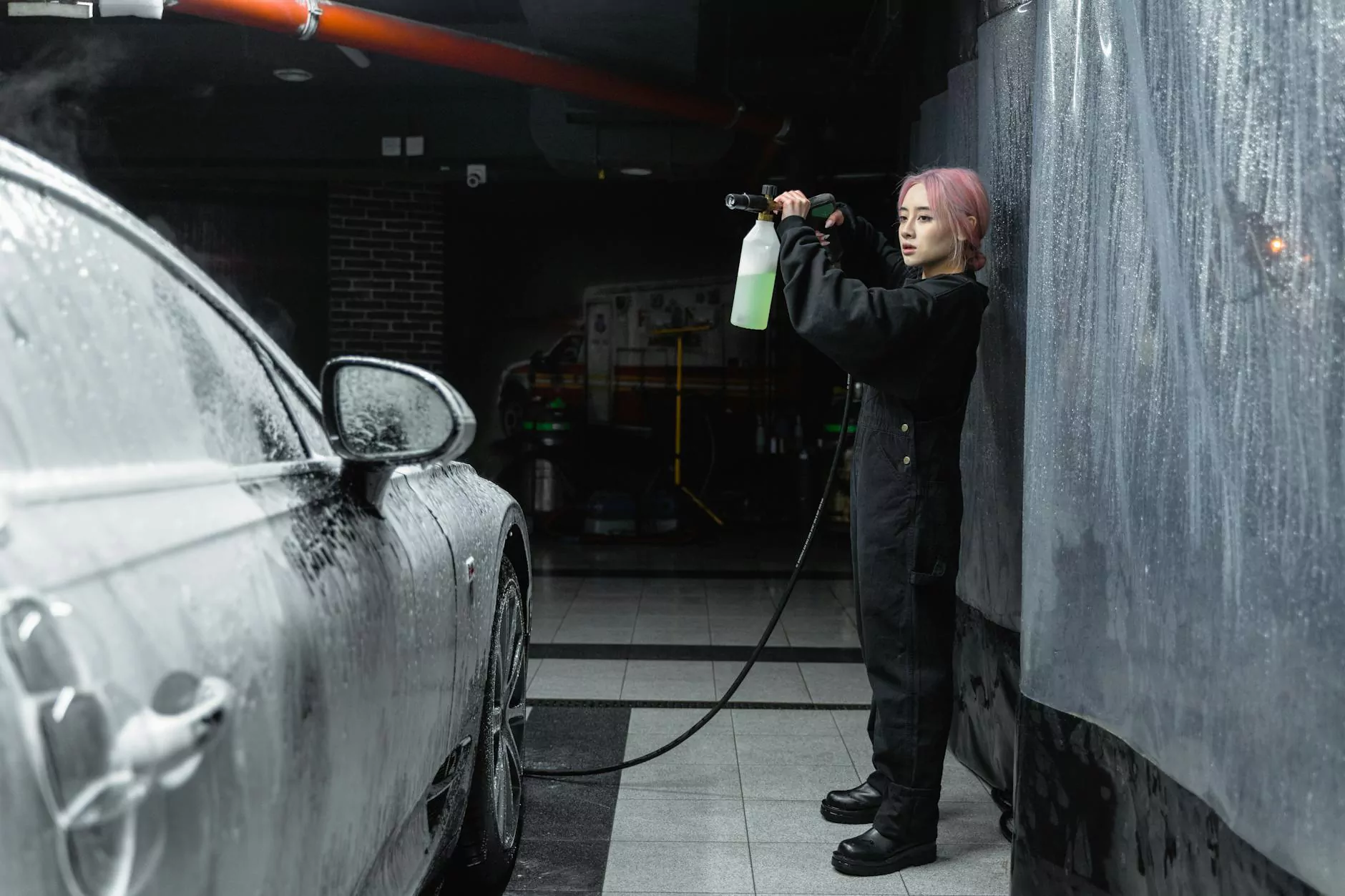

Non Skid Floor Coating can be applied in various settings, catering to different commercial needs. Some of the most common application areas include:

- Industrial Facilities: Factories and warehouses often require high-traction surfaces due to heavy machinery and foot traffic.

- Hospitality Industry: Hotels and restaurants benefit from non skid coatings in kitchens, bathrooms, and dining areas.

- Retail Spaces: Stores can enhance safety for customers in high traffic areas, especially during wet conditions.

- Healthcare Institutions: Hospitals and clinics must prioritize safety to protect patients and staff from falls.

- Transportation Hubs: Airports and bus stations require durable, safe flooring for the safety of travelers.

Types of Non Skid Floor Coatings

There are various types of Non Skid Floor Coating available, each designed to meet specific needs and conditions. Understanding these options will help you choose the best coating for your business:

- Epoxy Coatings: Ideal for industrial settings, epoxy creates a robust, slip-resistant surface that's highly durable.

- Polyurethane Coatings: These coatings are more flexible than epoxy, making them suitable for areas with varying foot traffic.

- Slip Resistant Paint: Perfect for lighter-duty applications, this paint offers a quick and cost-effective solution for safety.

- Textured Coatings: These surfaces have a higher profile, providing excellent traction in wet areas.

Choosing the Right Non Skid Floor Coating

Selecting the appropriate Non Skid Floor Coating involves several considerations. Here are some factors to keep in mind:

- Type of Facility: Consider the nature of your business and the specific requirements of your environment.

- Foot Traffic: Evaluate the volume of traffic your floors will experience to determine the necessary durability.

- Environmental Conditions: Assess whether your floors will be exposed to moisture, chemicals, or heavy machinery.

- Budget: While investing in quality coatings is important, keep your budget in mind to find the right balance.

The Application Process of Non Skid Floor Coating

The application of Non Skid Floor Coating is a specialized process that should be handled by professionals to ensure safety and effectiveness. Here is an outline of the typical process:

- Preparation: The surface must be thoroughly cleaned and prepped, which may include grinding or shot blasting to promote adhesion.

- Priming: A primer may be applied to ensure the coating bonds properly to the substrate.

- Application of Coating: The non skid coating is applied using appropriate techniques such as rolling or spraying.

- Adding Texture: Depending on the type of coating, a texturing agent may be added to achieve the desired level of slip resistance.

- Curing: After application, the coating requires time to cure before it's open to foot traffic.

Maintaining Your Non Skid Floor Coating

Once your Non Skid Floor Coating is applied, regular maintenance is crucial to ensure its longevity and effectiveness. Here are some tips for maintenance:

- Regular Cleaning: Keep the flooring clean to prevent dirt buildup which can reduce traction.

- Prompt Repair: Address any damages immediately to maintain safety and aesthetics.

- Periodic Inspections: Regularly inspect the coating for wear and tear, and assess if reapplication is necessary.

Conclusion

In conclusion, utilizing Non Skid Floor Coating is one of the best decisions a business can make to enhance safety, aesthetics, and functionality. By understanding the types and advantages of these coatings, you can create a secure and appealing environment that reflects the values of your business. If you're ready to transform your floors and increase safety in your workplace, consider partnering with experts like ND Clean to get the job done efficiently and effectively. With proper application and maintenance, your Non Skid Floor Coating will provide long-lasting results that benefit both your employees and customers.